ʻO Superalloy InconelX-750/ UNS N07750/ AlloyX-750 Paipu Seamless, Pepa, Uea

Nā Huahana Loaʻa

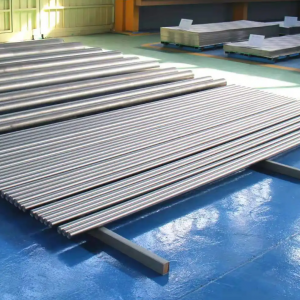

Paipu maʻemaʻe ʻole, Pāpaʻa, ʻOkoʻo, Paʻa, Paʻa, Paipu Paipu

Nā Kūlana Hana Hana

| Huahana | ASTM |

| Nā Paʻa a me nā Forgings | B 637 |

Hoʻohui Kimia

| % | Ni | Cr | Fe | C | Mn | Si | S | Ti | Nb+Ta | Al | Co | Cu |

| Min | 70.0

| 14.0 | 5.0 |

|

|

|

| 2.25 | 0.70 | 0.40 |

|

|

| Max | 17.0 | 9.0 | 0.08 | 1.00 | 0.50 | 0.010 | 2.75 | 1.20 | 1.00 | 1.00 | 0.50 |

Na Waiwai Kino

| ʻO ka mānoanoa | 8.28 g/cm3 |

| hehee | 1393-1427 ℃ |

Nā hiʻohiʻona o Inconel X-750

ʻO Inconel X-750 alloy ka mea nui i ka nickel-based superalloy i hoʻoikaika ʻia i ka makahiki me ka γ [Ni3(Al, Ti, Nb)].Loaʻa iā ia ka pale corrosion maikaʻi a me ke kūpaʻa oxidation ma lalo o 980 ℃, a ma lalo o 800 ℃ He kiʻekiʻe ke kūpaʻa corrosion.Loaʻa iā ia ke kūpaʻa hoʻomaha maikaʻi ma lalo o 540 ° C, a me ka formability maikaʻi a me ka weldability.Hoʻohana nui ʻia kēia alloy no ka hana ʻana i nā mīkini mokulele e hana ana ma lalo o 800 ° C a koi i ka ikaika kiʻekiʻe..Hiki ke hoʻohana ʻia nā pūnāwai no ka hana ʻana i nā lau turbine turbine mahu a me nā ʻāpana ʻē aʻe, e like me nā papa, nā ʻāpana, nā kaola, nā forgings, nā apo, nā uwea, nā paipu, etc.

ʻO ke kaʻina hana wela o Inconel X-750

ʻO ka ʻōnaehana hoʻonā wela no nā papa, nā ʻāpana a me nā paipu i ka mokuʻāina hoʻolako ʻo 980 ℃ ± 15 ℃, hoʻoluʻu ea.No ka ʻōnaehana mālama wela waena o nā mea a me nā ʻāpana, hiki ke koho ʻia nā kaʻina hana no ka mālama wela.

Hoʻopili: 955 ~ 1010 ℃, hoʻoluʻu wai.

ʻO ka hoʻopili ʻana i nā ʻāpana welded ma mua o ka wili ʻana: 980 ℃, 1h.

ʻO ka hoʻoluhi hoʻoluhi hoʻoluhi ʻana o nā ʻāpana welded: 900 ℃, hoʻomaʻemaʻe no 2h.

Ka hoʻoluhi hoʻoluhi ʻana i ka pilikia: 885 ℃ ± 15 ℃, 24h, hoʻoluʻu ea.

ʻO Inconel X-750 nā ʻano like ʻole a me nā kikoʻī

Hiki ke hoʻolako ʻia nā ʻāpana, nā forgings, nā apo, nā ʻili wela, nā ʻili anu, nā ʻili, nā paipu a me nā uea i nā ʻano nui.

Hāʻawi ʻia nā papa a me nā ʻāpana ma hope o ka ʻōwili wela a i ʻole ke anu, annealing a i ʻole solution, pickling a polishing.

Hiki ke hoʻolako ʻia nā pahu, forgings a me nā apo i ke kūlana forged a i ʻole ka wela wela;hiki ke hoʻolako pū ʻia i loko o ka lāʻau hoʻonā ma hope o ka hoʻopaʻa ʻana;Hiki ke hoʻolako ʻia nā pahu ma hope o ka hoʻonā ʻana a hoʻoliʻi ʻia a huli ʻia, a hiki ke hoʻolako ʻia i ke anuanu ke koi ʻia ke kauoha e huki i kahi kūlana.

Hiki ke ho'olako 'ia ka uea ma ke kūlana ho'onā pa'a;no ka uea me ka anawaena inoa a i ʻole ka mānoanoa ma lalo o 6.35mm, hiki iā ia ke hoʻonā paʻa a hāʻawi ʻia me kahi deformation kaha kiʻi anuanu o 50% a 65%;ʻoi aku ka nui o ke anawaena inoa a i ʻole ka lōʻihi ʻaoʻao ma mua o 6.35mm.ʻO ka uea, ma hope o ka hoʻoponopono ʻana i ka hopena, ua hoʻolako ʻia me kahi deformation huki anuanu ʻaʻole i emi ma lalo o 30%.No nā uea me ke anawaena inoa a i ʻole ka lōʻihi o ka ʻaoʻao ʻaʻole i ʻoi aku ma mua o 0.65mm, hiki ke hoʻolako ʻia me ka deformation huki anu ʻaʻole i emi iho ma lalo o 15% ma hope o ka mālama ʻana i ka hopena e like me ka mea e pono ai.

Nā Wahi Noi ʻo Inconel X-750

Hoʻohana nui ʻia ka alloy no ka hana ʻana i nā puna lau a me nā pūnāwai coil me nā koi ikaika kiʻekiʻe a me ke kūpaʻa hoʻomaha no nā aero-engine e hana ana ma lalo o 800 ° C.Hiki ke hoʻohana ʻia e hana i nā ʻāpana e like me nā lau turbine.ʻO nā ʻano ʻano like ʻole he pepa, strip, bar, forging, apo, wire and tube.